- About us

- Products

- Capsule House A Series

- Capsule House K Series

- Apple Cabin E Series

- Capsule House X Series

- Tiny House

- Floating House

- Capsule House U Series

- Apple Cabin D Serires

- Capsule House M Series

- Capsule House H Series

- Capsule House Y Series

- Capsule House N series

- Capsule House T Series

- Service Stations

- Capsule House S Series

- Food Truck Series

- Project

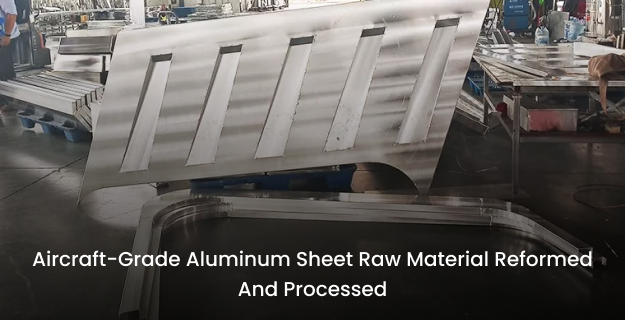

- Factory

- Service

- Media Hub

- Contact us